Astm A106b Yakakwirira chaiyo inotonhora yakakungurutswa isina musono pombi yesimbi

High-precision inotonhora-inodhonzwa precision simbi pombi rudzi rutsva rwepombi yesimbi, iyo inonyanya kukosha ndeyepamusoro.Kazhinji maviri-roller mill uye matatu-roller mill kugadzirwa kwemaitiro maviri ekugadzira, matatu-roller chigayo kugadzirwa kwechando chakakungurutswa seamless simbi chubhu precision yakakwira, inogona kudzorwa mukati mesiriki shoma, asi mutengo wakanyanya. -chaiyo inotonhora-inodhonzwa yakananga simbi machubhu kuchengetedza simbi, kunatsiridza kushanda zvakanaka, kuchengetedza simba Iyo inonzi yakakwirira-chaiyo inotonhora-inodhonzwa seamless simbi chubhu inoreva mukati nekunze dimensional kurongeka (tolerance range) yakasimba, yemukati nekunze. kupedzisa, kutenderera, kutwasanuka, kunogona kuchengetedza zvakanyanya maawa ekugadzira, kunatsiridza mashandisirwo emidziyo, uku ichibatsira kuvandudza mhando yechigadzirwa.

Iyo huru inotonhora yekugadzirisa nzira dzesimbi pombi inotonhora kudhirowa uye kutonhora kukungurutsa nzira.Mumakore achangopfuura, nekuvandudzwa kwesainzi uye tekinoroji, uye kugadzirwa kweinotonhora kuruka nzira, neiyi nzira inogona kuburitsa dhayamita hombe, yakakwirira-chaiyo inotonhora-yakakungurutswa machubhu uye inotonhora-yakakungurutswa machubhu ane chinja-chinjika-chikamu.Cold processing yesimbi pombi mbishi zvinhu zvinogona inopisa-yakakungurutswa musono simbi pombi inogona zvakare welded pombi.Chinhu chakajairika cheiyo inotonhora yekugadzirisa nzira yepiipi yesimbi ndeye yakakwira dimensional kurongeka, kunaka kwepamusoro roughness, inogona kuburitsa yakanyanya kutetepa (kusvika 0.05 ~ 0.01mm) machubhu akatetepa-ane madziro uye akanyanya kunaka (dhayamita kusvika 0.3 ~ 0.1 mm) capillary. machubhu.Seamless steel pombi mapaipi ane hollow cross-section, ayo anoshandiswa muhuwandu semapaipi ekutakura mvura, semapaipi ekutakura oiri, gasi rechisikigo, gasi, mvura uye zvimwe zvinhu zvakasimba.Kuenzaniswa nesimbi yakasimba senge simbi yakatenderedzwa, pombi yesimbi inoreruka pakurema kana kupeta uye kusimba kwesimba kwakafanana, uye isimbi yehupfumi inoyambuka, iyo inoshandiswa zvakanyanya muinjiniya yepombi.

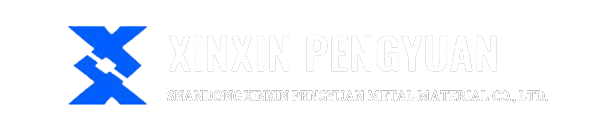

Kugadzirwa :ProcessRound chubhu isina chinhu →kupisa → kubaya → matatu-roller skew kutenderedza, kuenderera kutenderedza kana extrusion → kubviswa kwechubhu → saizi (kana kuderedza) → kutonhorera → kutwasa → hydrostatic bvunzo (kana kuona kukanganisa) →maka → yekuchengetedza isina musono pombi yesimbi Iyo yakagadzirwa nesimbi ingots kana yakasimba chubhu blanks kubudikidza perforation kugadzira capillary chubhu, uye ipapo inopisa-akakungurutswa, kutonhora-akakungurutswa kana kutonhora-inodhonzwa.

1.Structural seamless pombi

(Seamless simbi mapaipi ekugadzira mapaipi, ngarava, midziyo, mafittings uye michina zvimiro)

2.Seamless pombi yekufambisa kwemvura

(Mapombi anoshandiswa kutakura zvinwiwa ipombi dzekutakura oiri, gasi rechisikigo, gasi, mvura uye zvimwe zvinhu zvakasimba.)

3.Seamless chubhu yebhairi.

4. Pombi yekufambisa: Inonyanya kushandiswa pakufambisa mvura, oiri uye gasi.

5. Pipe yemutsara: Inonyanya kushandiswa pakudzivirira mutsara

6.Auto zvikamu, hydraulic steel pipes

1. Sei muchitisarudza?

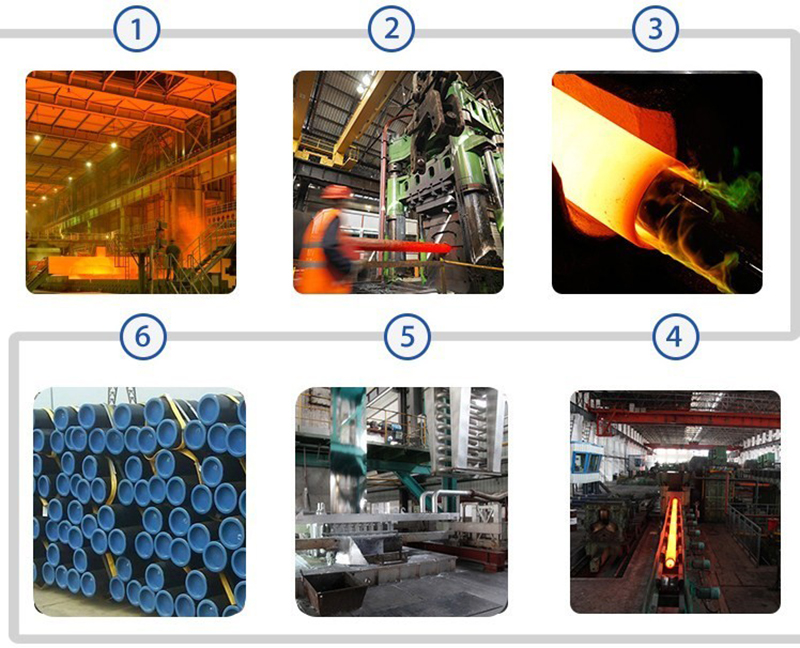

Kambani yedu yave nemakore gumi nemaviri.Isu tinodzora mhando yezvigadzirwa zvakanyanya kuomarara, kune vanhu vakakosha kune mhando.

Kana iwe uine mutengo wakaderera kubva kune mumwe mutengesi, isu tichabhadhara kaviri kune vatengi nezve mutengo wepamusoro.

2. Yakareba sei nguva yako yekuendesa?

Zvinoenderana nehuwandu.Kazhinji mukati memazuva 2-7 kana mune stock.Uye 15-20 mazuva kana asiri mustock.

3. Ndeipi mitemo yako yekubhadhara?

A: NeT/T 30% pachine nguva, uye 70% isati yasvika.

B:100% L/C pakuona.

C:Ne T/T 30% pachine nguva, uye 70% L/C pakuona.

4. Unopa samples here?Ndeyemahara here?

Hongu, isu tinopa sampuli yemahara asi hatibhadhare mutengo wekutakura.

5. Zvakadini kana mutengi asina kugutsikana?

Kana paine dambudziko nechigadzirwa, tinotora mutoro wakazara.